Raw Material and Product Management

- Quality Assurance and Management

- Appropriate Management of Chemical Substances

- Promoting Product Stewardship through the Product Life Cycle

Quality Assurance and Management

Providing High Quality Products

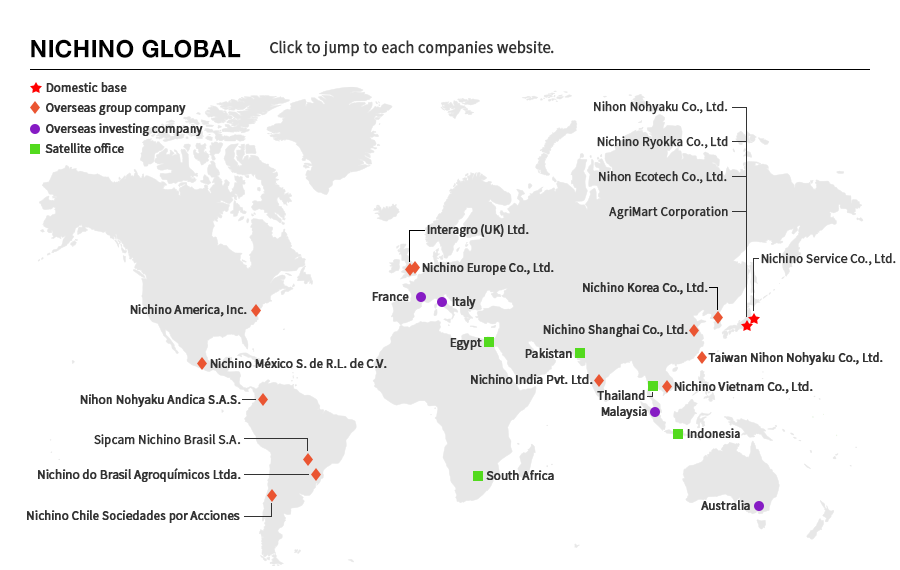

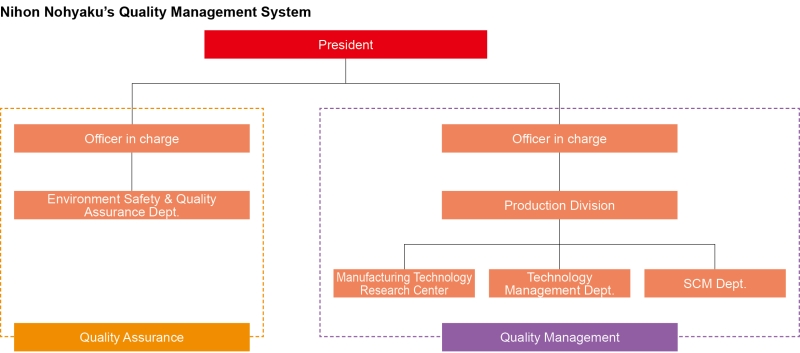

We work to ensure product quality and safety in every stage of the value chain, from R&D through manufacturing, sales, logistics, use, and final consumption to disposal and recycling, based on our basic policy for Responsible Care. To fortify supervision and control functions, we have consolidated the quality assurance function into the Environment Safety & Quality Assurance Department. Product quality is handled by two departments, the Environment Safety & Quality Assurance Department, which handles quality assurance, and the Production Division, which handles quality control. We carefully deliberate with Nichino Service, the Group’s manufacturing company, to manage quality with a focus on their maintenance and improvement. In our production process for active ingredients*1, we practice quality management that applies GMP management methods (production management and quality management standards for pharmaceuticals).

The Environment Safety & Quality Assurance Department conducts audits on contract manufacturers outside the Nihon Nohyaku Group from an independent standpoint. We conduct risk management for product liability (PL*2) to prevent issues. In addition, we visualize the status of responses to complaints received in relation to our products with an internal database to promote rapid and accurate response.

*1 Active ingredients of agrochemicals

*2 Product Liability

Appropriate Management of Chemical Substances

The Group creates Safety Data Sheets (SDSs) for agrochemicals, products excluding agrochemicals, and samples for testing and research purposes to ensure the safe handling of chemical substances and prevent injuries and accidents. We also display information about agrochemical products on the corporate website. In FY2023, we focused on revising the SDSs of each item to comply with the revised Industrial Safety and Health Act that went into effect on April 1, 2024. We also appointed chemical substance managers and protective equipment managers at business offices where chemical substances are handled in accordance with the revised Industrial Safety and Health Act, and took the necessary measures. We have built an SDS library on the company intranet to enable the Group’s plants and offices to view SDSs when needed - including SDSs of raw materials and products.

Promoting Product Stewardship through the Product Life Cycle

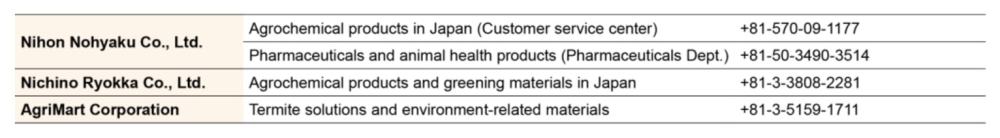

The Group focuses on safety management throughout the product life cycle, from research to manufacturing, use, and disposal, and provides appropriate information. Particularly during the research and development stage, we conduct voluntary audits based on our own internal regulations, and continuously engage in initiatives to ensure product safety, also known as “Product Stewardship.” In addition, we have set up a phone number and a contact form on our website, as points of contact for inquiries and consultation regarding our various products and agrochemicals in general.

We provide the Japan Poison Information Center with SDSs of our products to assist in inquiries from medical institutions, in the unlikely event of a poisoning accident related to our products.