Occupational Safety & Health, Process Safety & Disaster Prevention

- Global Zero Accidents

- Global Occupational Safety Audit System

- Avoiding Accidents in the Research Stage

- Eliminating Serious Accidents at Production Sites

Global Zero Accidents

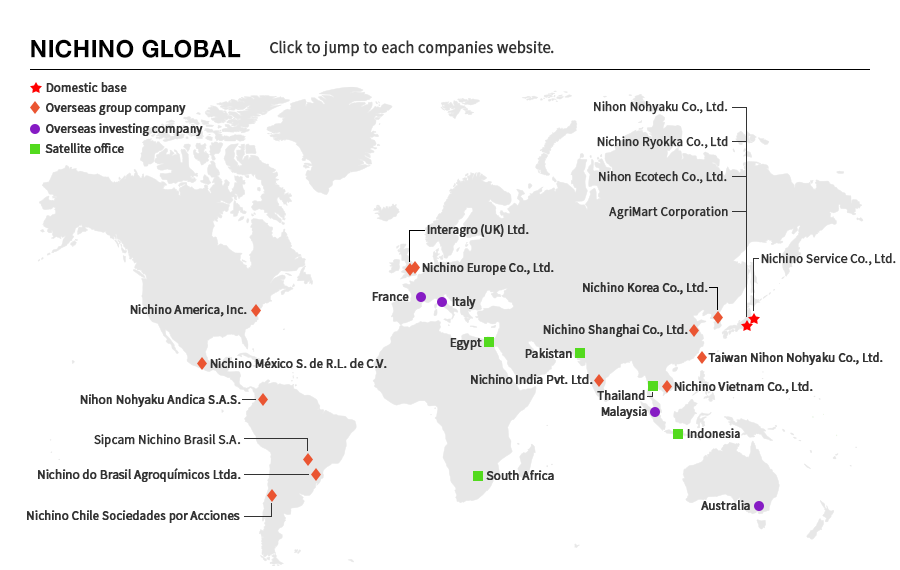

As part of the Responsible Care activities, Group companies in Japan work toward the goal of achieving zero occupational/commuting accidents and serious equipment-related accidents through the Occupational Safety & Health and Process Safety & Disaster Prevention Code. Regular safety and health committee meetings are held at all sites, regardless of whether they are offices, laboratories, or other facilities. Furthermore, all commercial vehicles are equipped with dashboard cameras, and ratings of driving by insurance companies are used to raise awareness about safe driving. Group companies that have manufacturing sites outside Japan work toward achieving zero accidents through efforts such as using ISO45001 (Occupational Safety & Health Management System). We plan to continue expanding Responsible Care activities outside Japan so that the entire Group can work together to carry out occupational safety & health and process safety & disaster prevention initiatives through Responsible Care activities.

Global Occupational Safety Audit System

The Environment Safety & Quality Assurance Department conducted (twice in total) on-site and written audits of overall Responsible Care activities, including occupational safety and health, at all plants and offices of Group companies in Japan to enhance monitoring and check-and-balance functions. Audits consist of confirming whether there have been accidents at worksites and providing instruction on improving the safety of offices’ activities. Globally, in FY2023, we conducted on-site inspections of our manufacturing sites, Nichino India (India) and Sipcam Nichino Brasil (Brazil), to confirm and provide guidance on their safety management systems. Going forward, we plan to develop a global audit system based on Responsible Care and ISO methods and to audit offices in the Group outside Japan.

Avoiding Accidents in the Research Stage

Firefighting Technique Training Session Winner’s Cup and Certificate (Research Center)

Firefighting Technique Training Session Winner’s Cup and Certificate (Research Center)

To implement a high level of safety management for research activities at the NICHINO Group’s research sites, we continuously encourage employees to acquire national qualifications, such as hazardous materials handler qualifications, to increase the number of qualified personnel. We also conduct safety activities with an emphasis on avoiding accidents through Kiken Yochi (risk prediction) activities, risk assessment, safety education, and safety patrols led by sites’ safety and health committees. In the unlikely event of an accident, various drills are conducted to minimize damage. In FY2023, the in-house fire fighting team won the indoor fire hydrant category at the Firefighting Technique Training Session in Kawachinagano-city, Osaka. We carry out safety activities from a wide range of approaches, such as conducting risk assessments based on actual accidents that occurred at other offices and conducting multifaceted safety research from the early stages of research.

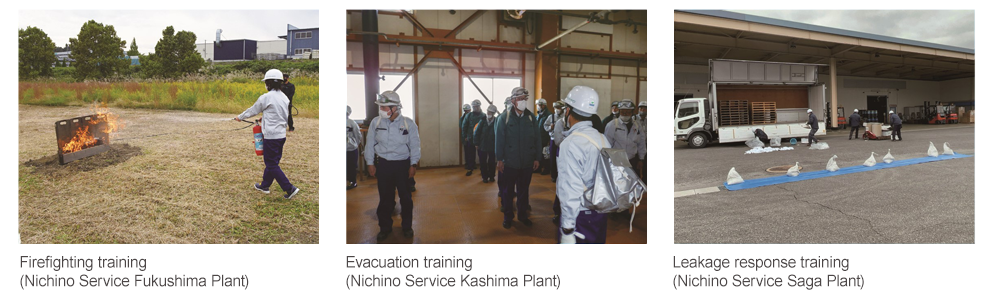

Eliminating Serious Accidents at Production Sites

All of our production sites have acquired ISO45001 and promote safety activities and equipment maintenance using an Occupational Safety & Health Management System. Nichino Service carries out risk assessment on a 5-stage scale, and with a company policy of eliminating level 3 or higher risks, it works to reduce risks by reviewing work procedures and improving equipment based on the results of assessment. We have also started deliberations on developing an intelligent and automated smart factory that considers not only production efficiency but also safety. We strive to prevent and eliminate accidents at our overseas production sites. Going forward, we plan to carry out initiatives to improve our management level through regular inspections and audits.